top of page

Buck Knives: "The Range Series"

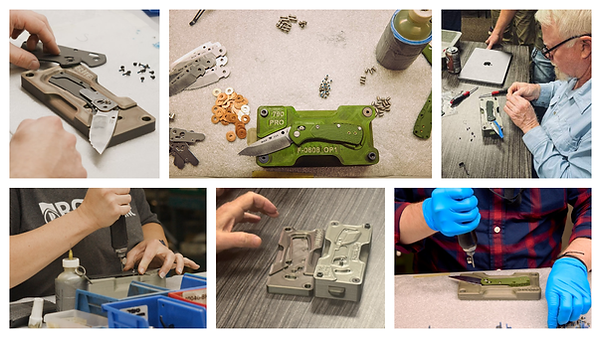

Assumed responsibility for the Range Series in January 2024 after a failed pilot run threatened the project’s viability. By re-engineering failed lock mechanics and implementing DFM optimizations, I rescued the project’s schedule and budget for its successful launch in September 2025.

Key Skills

Reverse Engineering & Analysis

Reverse engineered competitor products to deconstruct and map critical lock geometries, engagement angles, and tight-tolerance zones. This data pinpointed the mechanical flaws of earlier revisions, establishing the necessary parameters for the redesign.

Mechanism & Tolerance Design

Re-engineered lock geometry and tolerance stack-ups to eliminate blade play and minimize lock stick. Optimizing the tang-to-lock interface and fastener specs delivered a "vault-tight" lockup and improved production consistency.

*Images courtesy of: Buck Knives Inc. and Blade HQ

DFM & CNC Optimization

Redesigned handle components to accommodate high-efficiency tooling and developed custom tool paths to eliminate time-intensive 3D rastering. These optimizations reduced CNC cycle times by 50% while improving handle function and maintaining aesthetic features.

Tooling Constrained Redesign

Restored product performance by engineering "steel-safe" part modifications and a strategic material change to salvage existing injection mold tooling. This approach bypassed the need for new capital expenditure while working within the fixed constraints of original fine-blanking dies.

*Images courtesy of : Hook & Barrel Magazine, Knife Magazine, and Buck Knives Inc.

Mechanical Fixture Engineering

Engineered spring-loaded fixtures to facilitate a linear build process and drastically accelerate product rework. The custom mechanism ensured precise alignment and eliminated redundant handling, increasing throughput for both initial assembly and part replacement.

bottom of page